New Step by Step Map For precision machining

What exactly are the constraints of precision machining? You will find lessons for college students who usually takes precision machining. An organization termed Option Precision Machine states There exists not limitation of distance or job With regards to shop producing.

Precision machines use a cutter and may be solid cutters which include tungsten carbide, cobalt or HSS. Watercutters that happen to be very exact and use incredibly superior stress drinking water. These are typically used by Britool to cut spanners away from one/two" (12.seven MM) metal plate. Laser cutters make use of a beam to erode the surface area but these models are still pretty expencive and therefore are hardly ever seen in workshops.

When supplemental dimensional confirmation of element accuracy is needed, 4 Zeiss Coordinate Measuring Devices are offered to ascertain evidence that this precision continues to be attained.

The smart Trick of machining That Nobody is Discussing

The goal of SPC is to uncover these changes as well as their resource inside of a well timed method so that the procedure can be corrected.

Photochemical Machining: "Is a process of making use of photoresist to protect the floor of metallic, though using an etchant to dissolve away chosen regions."

A drill can be utilized to eliminate metal in The form of a cylindrical hole. Other tools That could be employed for different kinds of metallic elimination are milling equipment, saws, and grinding machines. Many of these exact same techniques are used in woodworking.

The developments with the 1860s opened the floodgates and ushered in fashionable milling apply. 1870s to World War I[edit]

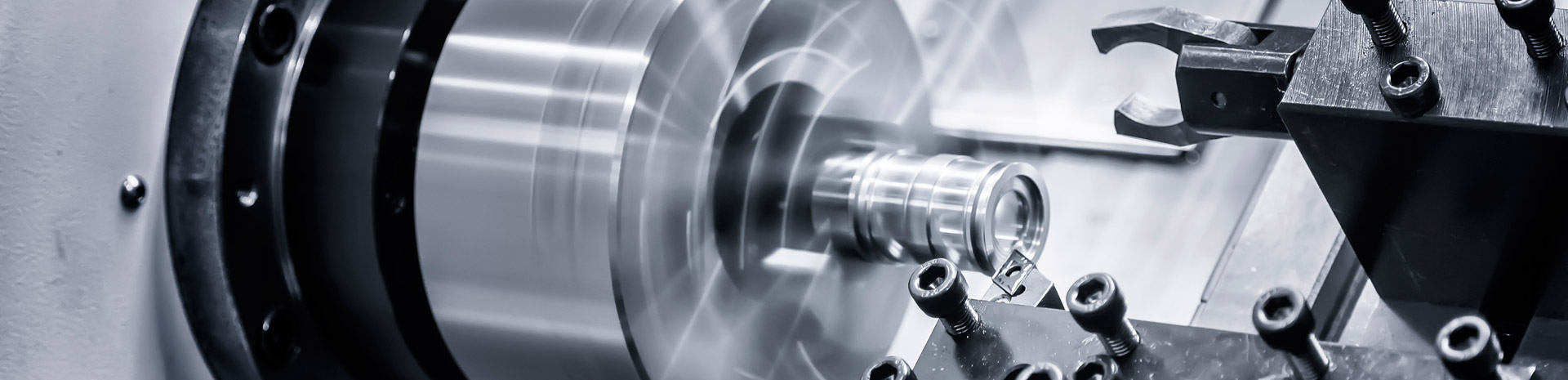

The mixing of milling into turning environments, and vice versa, commenced with Stay tooling for lathes as well as occasional use of mills for turning operations.

The 2-Minute Rule for machining

Nevertheless, two expectations that have noticed In particular wide use are the usinagem de precisão Morse #2 as well as R8, whose prevalence was pushed by the recognition of your mills designed by Bridgeport Devices of Bridgeport, Connecticut. These mills so dominated the market for this kind of quite a while that "Bridgeport" is just about synonymous with "handbook milling device". A lot of the devices that Bridgeport made involving 1938 and 1965 employed a Morse taper #2, and from about 1965 onward most made use of an R8 taper. Add-ons[edit]

Impact Evaluation - Make Price-productive conclusions with a detailed influence Investigation for engineering and production adjustments

In turning, a reducing tool with one leading edge is employed to remove product from a rotating workpiece to make a cylindrical form.

Any time you use CNC machining to make a section, you're going to get curved locations where conclude mills can’t produce a sharp corner.

Top precision machining Secrets

CNC Industries wholeheartedly agrees that data management is crucial to a firm’s achievements. Their information and facts system has saved them innumerable hours and has facilitated just about excellent On-time Shipping and Good quality effectiveness.