Detailed Notes on machining

[two] The speeds and feeds made use of are different to accommodate a mix of variables. The pace at which the piece innovations in the cutter is called feed price, or perhaps feed; it's most frequently measured in size of fabric for each full revolution on the cutter.

Precision machined merchandise are all-around in day to day goods like car or truck engines, electric motors or even clocks. Nations for instance Switzerland and Germany Have got a popularity for there higher requirements of precision engineering and these days nevertheless do an excellent job of it. Other nations even have a lesser of this track record like Japan and Great Britian.

I used to be truly excellent at machining and would commit most of the working day on the machine chopping and drilling a bunch of different things.

Considerations To Know About precision machining

The Xometry Production Partner Network provides creation capacity and diverse machining capabilities for EDM pieces with even the tightest tolerances, most elaborate internal geometries, or augmented process requirements.

Planer-design mill (Plano Milling)Significant mills built in the same configuration as planers except which has a milling spindle in lieu of a planing head. This expression is developing dated as planers them selves are mostly a issue in the earlier.

Box mill or column mill Pretty standard hobbyist bench-mounted milling equipment that function a head Using up and down with a column or box way.

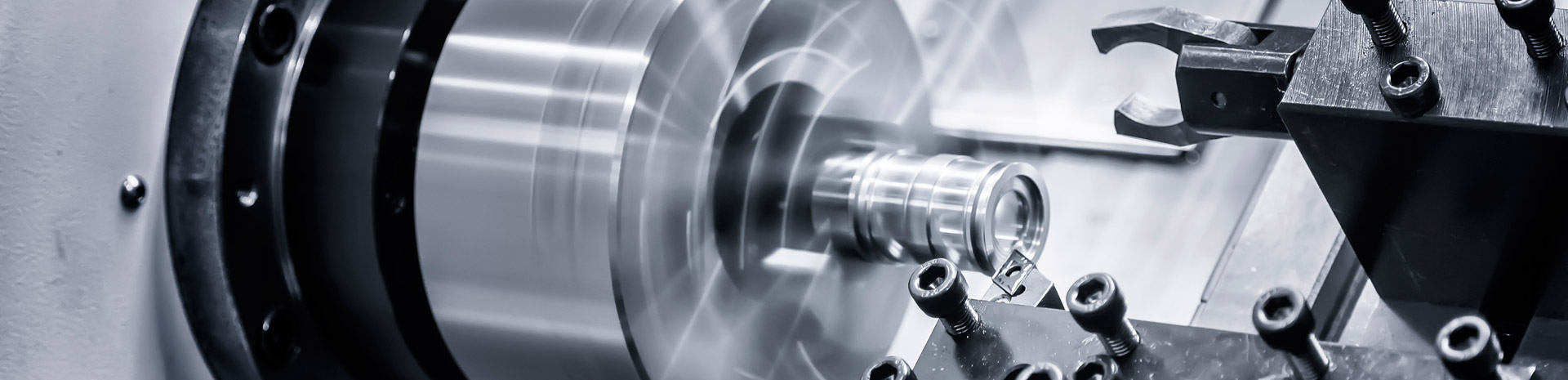

These machines are operated by specialized and experienced machinists. The precision machining process includes a reducing Resource that gets rid of material through the workpiece. To ensure that the chopping Instrument to carry out its career, it must be moved in Instructions specified for making the right Minimize. This Most important motion is known as the “chopping pace.†The workpiece may also be moved, often known as the secondary motion of “feed.†Alongside one another, these motions as well as sharpness from the reducing Software allow the precision device to operate. Find out more:

The chopping motion is shear deformation; materials is pushed off the workpiece in tiny clumps that cling with each other to the larger or lesser extent (based on the content) to kind chips. This can make metallic chopping somewhat diverse (in its mechanics) from slicing softer materials with a blade.

precision machining Fundamentals Explained

Tapped holes and inserts could be vital in the look of an element. Here's what we suggest to finest optimize your pieces.

To explain, be…ing precise doesn't equate to remaining accurate, for the reason that while one particular could possibly get hold of data which might be all extremely close, these facts might not be close to the real price. (Additional)

The late teenagers on the 19th century were being a pivotal time in the heritage of machine resources, as the period of 1814 to 1818 is also the interval in the course of which numerous contemporary pioneers (Fox, Murray, and Roberts) ended up establishing the planer,[23] and as While using the milling equipment, usinagem the do the job becoming carried out in a variety of outlets was undocumented for various reasons (partially as a result of proprietary secrecy, and also simply because not a soul was using down data for posterity).

As device dimension improves, transferring the knee up and down needs appreciable effort and hard work and Furthermore, it gets difficult to get to the quill feed deal with (if Geared up). For that reason, bigger milling equipment are generally of the bed form.

5 Tips about precision machining You Can Use Today

The choice amongst vertical and horizontal spindle orientation in milling device design normally hinges on The form and sizing of a workpiece and the quantity of sides in the workpiece that demand machining. Perform where the spindle's axial motion is normal to one plane, with the endmill because the cutter, lends itself to some vertical mill, in which the operator can stand before the machine and possess quick access on the slicing action by seeking down upon it.